One of the world’s most popular candies, gummy bears may range in size from a little 2.5 grams to a hefty 3.5 grams. People often refer to chewable candies as “gummy” or “gummi,” even though they contain no gum.

Ingredients In Gummy Bears

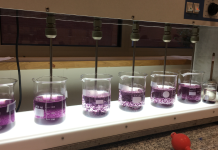

Expert food technologists and chemists usually create recipes for gummy candies. They may modify the candy’s texture, flavor, color, and appearance by adjusting the proportions of its various components. Ingredients include glucose syrup, sweetener, purified water, flavorings, and colorings, in addition to gelatin, pectin, and carrageenan. The Gummy Bear Machine can quickly and easily produce thousands of gummy bears.

Gummy Bear Machine: What Is It?

You may produce gummy machine of varying sizes and shapes with the help of a gummy bear machine, an automated candy manufacturing line controlled by PLC. A typical assembly line would include a stovetop, a depositor, candy molds, a cooling device, and the associated pumps, pipes, and other hardware.

Gummy Bear Machines: Why Invest?

- Gummy bears are a popular candy.

- Since the 1920s, gummy bears have been popular worldwide. Children and seniors are fans.

- The gummy bear machine can make CBD gummies, THC gummies, honey gummies, medicinal gummies, and functional gummies.

- Hygienic, low-cost, labor-saving starch-free gummy bear machine.

- Commercial gummy bear machine output ranges from 50kgs/h to 600kgs/h.

- Easy-to-use PLC-controlled gummy bear equipment.

- Gummy bears with filling, in several colors, with a second layer, and other novel confections are all possible with only one machine.

- Change your gummy bears to alternative shapes to save money.

Buying Gummy Bear Machines for A Business

- You should think about the following things if you want to acquire a gummy bear machine for commercial or industrial use:

- Affluent Manufacturer of high-quality gummy bear machines who can answer your questions quickly and provide sound advice.

- Excellent machinery for making gummy bears means you’ll have reliable production and little downtime.

- New confectionery techniques provide high returns and allow for various applications, including but not limited to gummy candies, hard candies, toffee, and lollipops (Customized design).

- The gummy bear machine has been certified by many organizations. Hire a professional monitoring service to do the task for you.

- Seeing is believing, so make sure you research and visit many gummy bear machine factories before making a final decision.

- Compare the gummy bear machine’s pricing, quality, brand components, materials, performance, and durability, and the supplier’s comparable project experiences, communication, and after-sales service response time.

Upkeep Of the Gummy Bear Machine

The service life of a gummy bear machine may be extended by keeping it in good functioning condition and doing routine maintenance. However, this only applies if the workers are adequately educated and acquainted with the technology. In case you were wondering, here is some upkeep guidance:

- You must heed all warnings.

- Observe the instructions outlined in the gummy bear maker’s user guide.

- Maintaining a clean passage and apparatus will reduce the risk of contamination entering the injury.

- Do not set the tool on the machine; return it to its original location.

- Make sure the electric cabinet and motor are watertight by cleaning them daily.

- The maintenance schedule includes oil changes for the pumps, reducer, and mechanical seal. Food-grade lubricant must be used if the lubricant might potentially come into contact with the food.

- Don’t panic if there’s an emergency; switch off the electricity.