RuggedPoly UHMWPE Block in Food Processing: Safe, Non-Toxic, and Hygienic

Food processing areas must follow strict safety and cleanliness rules every day. Machines in these places touch food that people eat later. Materials used in equipment must always be safe and non-harmful. They must also stay clean and resist damage from daily use. One material often used is called UHMWPE, a strong plastic. RuggedPoly uhmwpe block is one form used in food equipment. This material is known for durability, smooth surfaces, and safety. Understanding its benefits helps explain its role in food handling systems.

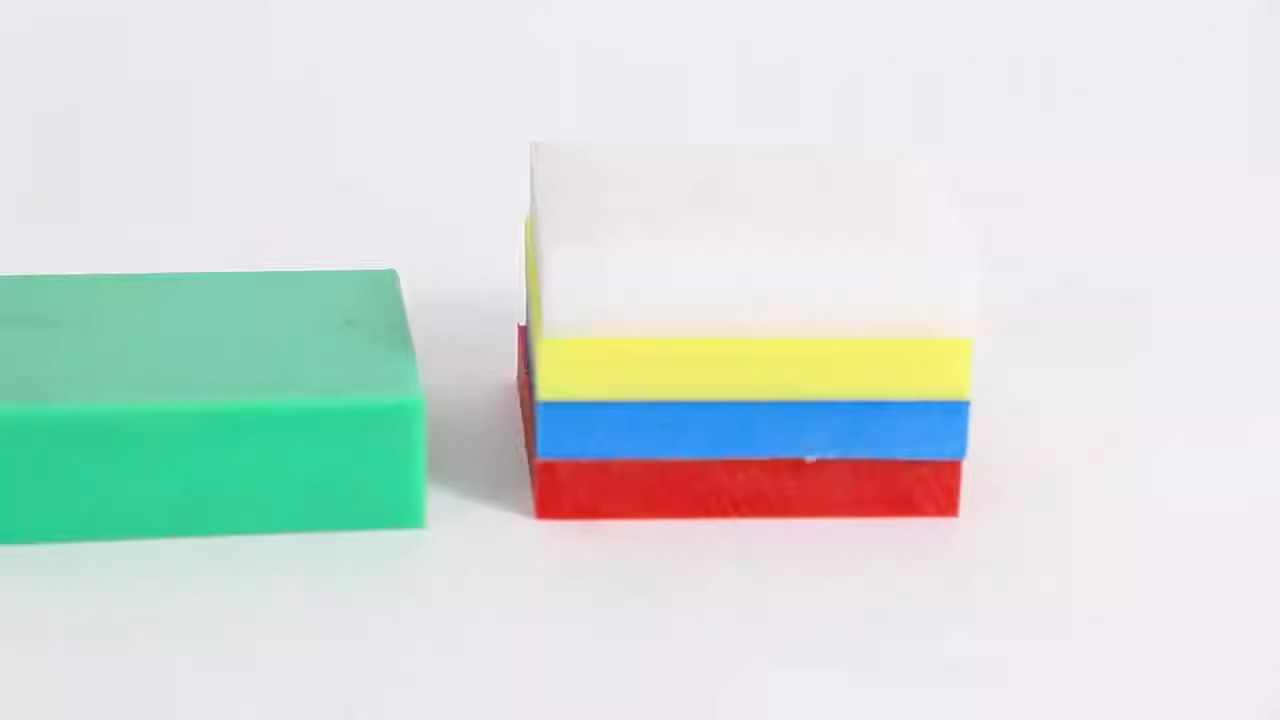

What UHMWPE Block Material Is

UHMWPE means Ultra High Molecular Weight Polyethylene. It is a highly dense plastic that is to be utilized intensively and repeatedly. The block form implies that the material is presented in the form of thick solid pieces. These blocks may be cut into sections for various machines. It is smooth on its surface and thus minimizes friction. It is also not easily worn off by continuous movement and contact. All these properties render it useful in food processing.

Safe and Non-Toxic for Food Contact

In processing and packaging plants, food safety is of great importance. The materials that come in contact with food should not emit toxic elements in the long run. UHMWPE has been identified as non-toxic when used in food. This allows it to be used in components that are likely to come into direct contact with food. The material is not reactive to food or liquids. This aids in the preservation of foodstuffs in the process of handling and transportation.

Hygienic Surface That Is Easy to Clean

Contamination should be avoided by ensuring that food factories have clean surfaces. The surface of the UHMWPE Block has a smooth and non-porous structure. Non-porous, which means that it is not easy to absorb liquid or particles. This helps in getting rid of the dust, food, or wetness. During regular washing, these surfaces become easy to clean for the workers. Simple washing promotes the hygiene situation in the food processing zones that are crowded.

Resistance to Moisture in Wet Environments

The processing of food is associated with the use of water, steam, and regular washing. There are those materials that swell or weaken when they are in prolonged contact with moisture. UHMWPE is not able to receive water from the surrounding environment. This assists the block to retain its size and shape over time. Stable shape supports proper fitting of machine parts and components. Moisture resistance also helps maintain hygienic working conditions consistently.

Strong Wear Resistance During Constant Use

Machines in food plants run for many hours every day. Parts slide, rotate, and move while handling food products continuously. This movement can wear down weaker materials very quickly. UHMWPE Block resists abrasion and surface wear during long operation. Wear resistance helps parts last longer without frequent replacement. Longer part life supports steady machine performance in processing lines.

Low Friction Helps Smooth Food Handling

Friction can slow movement and cause surface damage inside machines. UHMWPE Block has a naturally low-friction surface. This allows products and parts to move more smoothly. Smooth movement helps prevent jams and uneven handling of food. It also reduces stress on machines during long working shifts.

Chemical Resistance in Cleaning Processes

The cleaning agents in food factories are used to maintain the cleanliness of equipment. There are some materials that are ruined when subjected to these cleaning chemicals. UHMWPE resists a wide range of chemicals commonly used. This helps the material keep its strength during regular cleaning cycles. Chemical resistance supports long-term reliability in food environments.

Lightweight but Strong for Equipment Design

Some strong materials are heavy and hard to work with. UHMWPE Block is lighter than many metal alternatives used in machines. Lighter parts can be easier to install and replace when needed. Despite lower weight, the material still offers high strength. This balance supports safe and practical equipment design in food systems.

Stability Under Impact and Pressure

Food processing equipment may experience pressure from moving products. Sudden impacts can also happen during machine operation. UHMWPE Block handles impact without cracking easily under stress. It also supports pressure from contact with food and parts. This strength helps protect both equipment and food handling processes.

Conclusion

Food processing needs materials that are safe, clean, and durable. RuggedPoly UHMWPE Block meets these needs in many systems. Its toxicity does not pose a threat due to its non-toxic quality. Non-porous surfaces make the working conditions hygienic on a daily basis. Moisture, wear and chemical resistance are also added to provide long-term reliability. Low friction supports smooth movement during food handling operations. Lightweight strength helps with machine design and maintenance tasks. Because of these features, the UHMWPE Block plays an important role. It helps food processing equipment stay safe, clean, and dependable.